A systematic approach reduces risk and speeds the journey from lab idea to stable production.

We start with function: Exactly what does the substance do (e.g., wetting, adhesion, gloss, barrier)? Then we shortlist candidates based on hazard, exposure, and function—not just “greener,” but right for the job. In the lab, we test real formulations and define key metrics early: color strength, durability, wash fastness, adhesion, and more. When a candidate holds up, we move to pilot and stress-test in production. Next, we “lock in” performance through process adjustments (temperature, drying, viscosity) and sometimes minor reformulations. Finally, we guarantee quality: documentation, change records, updated instructions, and follow-up on batch variation and customer feedback.

Our 5-step process:

- Map function and requirements.

- Alternatives analysis: hazard, exposure, function.

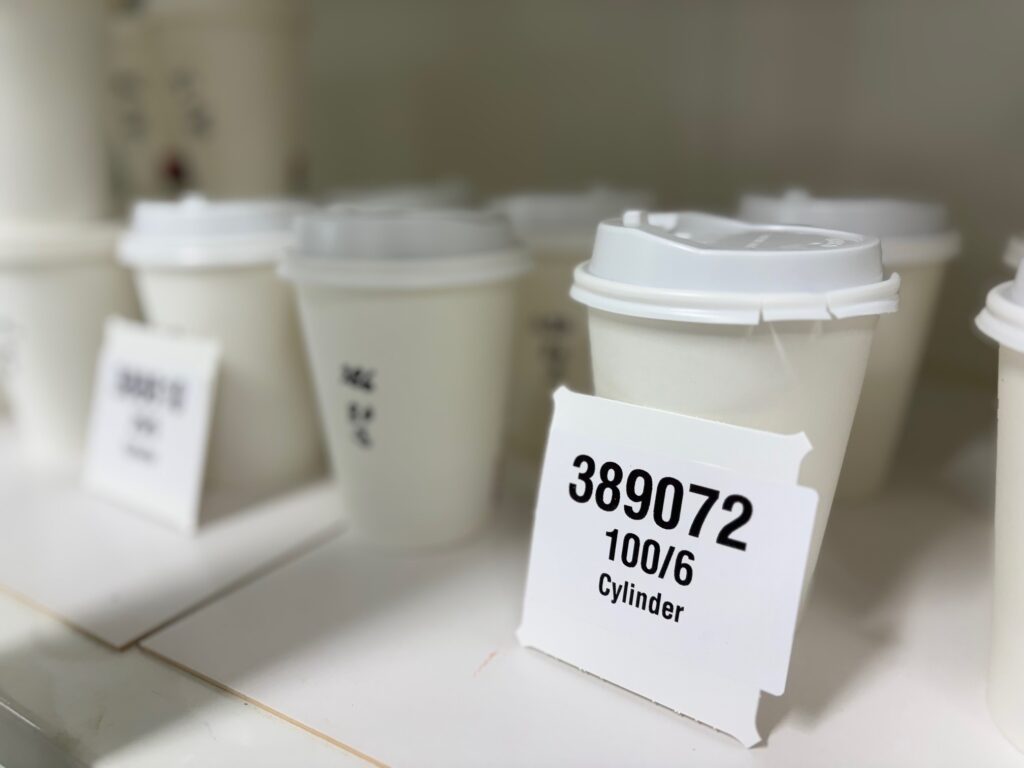

- Lab rounds in real formulations + clear metrics.

- Pilot/stress-test in production.

- Lock performance, document, and follow up.

Lessons learned: Measure the right things, work closely with suppliers, build in learning, and think holistically (quality, energy, waste, lifetime).

Need a starter kit for substitution projects? We can share a checklist for steps 1–3.

Coming in part 3: a concrete outcome from our approach—and what it means for customers.